Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Hannover Messe 22. - 26. April 2024

We’ll be there again! Check out for more details…

Excellence in digitalization

Award-winning projects and more to come with the new application round in 2024

Industry 4.0

The fourth industrial (r)evolution

Artificial Intelligence

Info & FAQs

Industry 4.0

The fourth industrial (r)evolution

Hannover Messe

Every year we are present with a joint booth and innovative exhibitors

Our partners

Industry 4.0

Industry 4.0 - what is that?

Best Practices

Contact

The networking of all activities in the value chain

What does Industry 4.0 mean?

People, machines and industrial processes are intelligently connected – that is Industry 4.0. Digitalisation has already arrived in industry and is developing rapidly. Increasingly it is finding its way into all sectors. This is accompanied by enormous opportunities and chances, but also risks and challenges. There ar megatopics such as artificial intelligence and cybersecurity. Training, further education, work and leadership are equally subject to the extensive changes and require new concepts.

Industry 4.0 – simply explained

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Too busy for innovations?

Industry 4.0 made in Baden-Württemberg

Competition "100 Places for Industry 4.0 in Baden-Württemberg"

In this competition, we were looking for outstanding solutions from industry and scientific research that are already being implemented. 200 projects from various sectors have been awarded. These best practices demonstrate how Baden-Württemberg is driving digitalization forward. At the same time they are a source of inspiration for other companies. Learn more

What innovations were awarded?

(1) new products, components, machines and plants,

(2) software and networking solutions,

(3) production and organisational processes, and

(4) new service offerings for industry and private customers.

More use cases and services

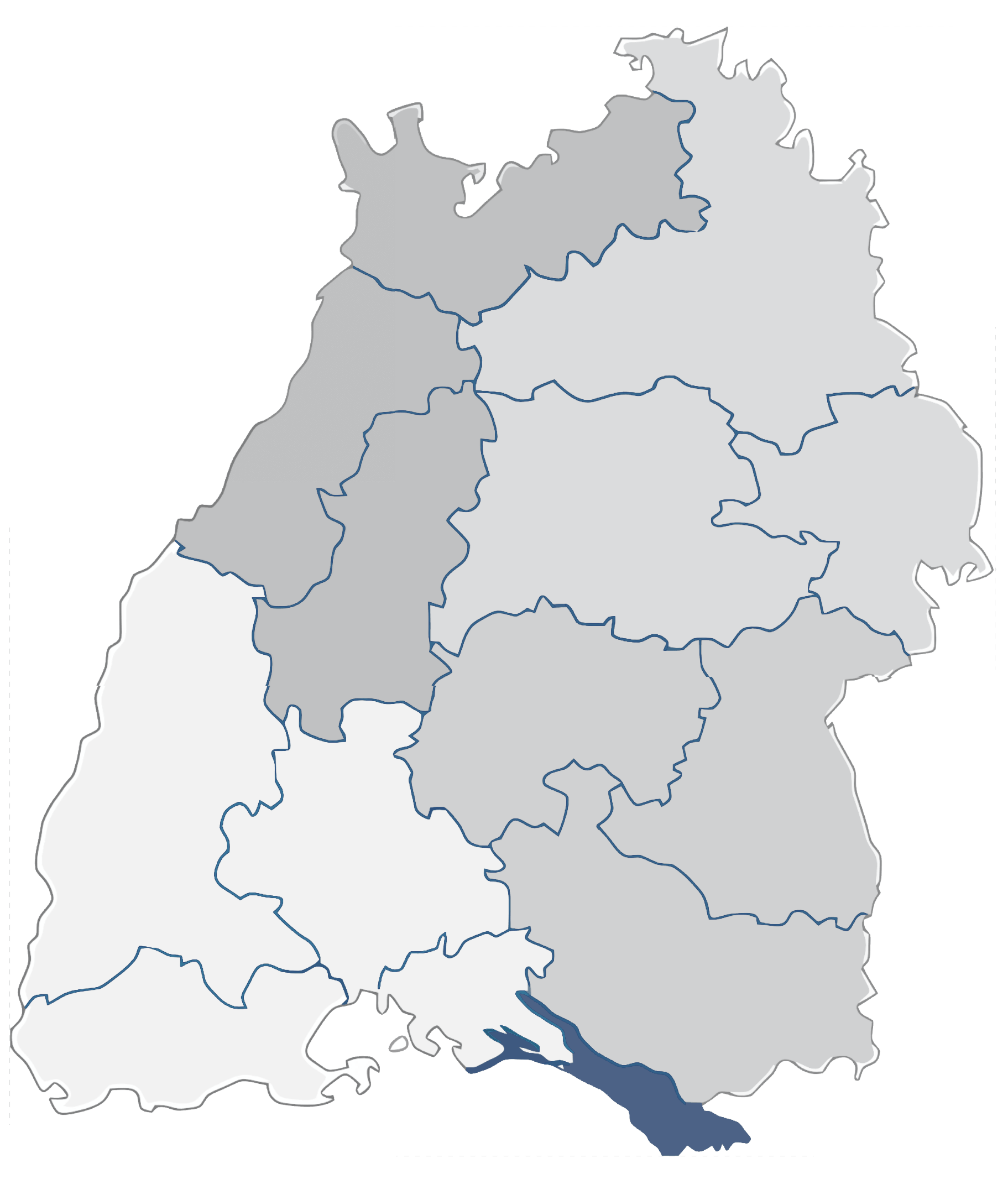

Industrie 4.0 map

The "Industrie 4.0 Map" of the Industrie 4.0 Platform depicts Industry 4.0 best practice examples, test centers, and information and support services throughout Germany.

Map "Wirtschaft digital"

On the map of the chambers of commerce, companies will find best practices as well as suitable support and consulting services.

There are neither universal "recipes" nor "blueprints" for digital transformation. Every company must find its own approach, answering the following question: How can we use digitalization to make the company, its employees, products and services better? With a digitalization strategy, new technologies, processes, and forms of work can be transformed from a secondary task into a core topic.

Jana Eiser-Mauthner

Project Manager

Artificial Intelligence Machine Learning Deep Learning Data Mining Neural Networks

Classification and terminology

FAQ on

Artificial Intelligence

AI map

Contact

Recognizing and exploiting the potential of Artificial Intelligence

Introduction to the topic of AI

Artificial Intelligence (AI) is currently attracting a great deal of attention in society and business worldwide. It provides companies with both the opportunity to offer new products and services on the market and to implement developed solutions in their own processes. At the same time, AI poses a challenge for companies and raises various questions: How and where can AI be used in a meaningful way? How and by whom does the implementation succeed? How can employees be involved in the process and how can they be trained?

FAQ AI

FAQ about artificial intelligence within the framework of digital transformation for manufacturing companies

FAQ

Häufige Fragen

AI is a sub-area of computer science. As there is no clear definition for the term “intelligence” itself, there are various definitions for the term AI. In addition, understanding of AI has been developing on an ongoing basis. In general, AI engages with tasks or problems which human intelligence is normally required to solve. These processes aim to create self-learning intelligence in the form of a system that can work independently to develop solutions for a problem. In this regard, AI includes a range of methods from mathematics, statistics and computer science, which reconstruct particular aspects of human intelligence, for example cognitive or sensorimotor intelligence. This reconstructed human intelligence is only limited to a very specific area of application.

It is important to note that AI does not only relate to simple automation in which an application is programmed to make a particular decision in the event of a particular input.

Read more:

See Question 3: What other terms relating to AI do I need to know and where can I find a clear explanation of the relevant terms?AI in manufacturing is a key technology, making it part of digital transformation and therefore a significant element of Industry 4.0. Within the framework of discussions relating to Industry 4.0 and the respective application scenarios, AI plays a key role, for example in the analysis of large data volumes and in automated decision-making. Thanks to comprehensive networking and the collection of large volumes of data, which are developments associated with Industry 4.0, AI solutions are improving in terms of performance and may be used in the manufacturing environment.

An example of this is predictive maintenance: Manufacturing systems and machines will be maintained in a predictive manner on the basis of intelligent data analyses instead of at fixed intervals. An application based on AI provides additional opportunities here in the field of data analysis and pattern recognition, which enables maintenance times to be optimised.

Read more:

PWC-study: Predictive Maintenance 4.0Huber: Case studies on Predictive Maintenance (in the Data Science book)

Data Mining refers to the use of algorithms for the analysis and processing of large, complex and heterogenous data sets (“big data”) to generate new information. In this regard, individual data components are brought together, in particular, in order to obtain new findings.

Machine learning is a sub-area of AI. The focus is on the development of algorithms that imitate the learning behaviour of the human brain for machines. The algorithms learn from experiences and can find solutions for new problems or evaluate unknown data sets.

Deep learning is a sub-area of machine learning that is characterised by complex solution methods. It uses artificial neural networks, in which multiple data processing levels can be combined.

Models that are based on artificial neural networks constitute the networking of nerve cells from a brain in an abstract form for information processing.

Weak artificial intelligence solves problems using methods that have been developed and optimised for the specific purpose (e.g. spam filters).

Strong artificial intelligence, also known as superintelligence , is superior to humans in terms of intellectual abilities. On the basis of the current knowledge, strong artificial intelligence does not yet exist.

For some of the terms that are listed, a concrete definition has not been established.

Read more:

Federal government: Artificial intelligence strategy of the federal government

Start-up scene: Artificial intelligence glossary

Elektronikpraxis Vogel: Artificial intelligence specialist terms

VDMA: Machine learning in machine and systems engineering

Fraunhofer Society: Artificial intelligence trends

Fraunhofer-Allianz Big Data: 2017 potential assessment for AI

AI is no longer just something for the future. AI is already making it possible to achieve significant progress in various areas of applications, for example in industry, the transport sector, healthcare and other areas of life. For AI applications it is important to identify solutions from the perspective of need and to evaluate AI as a tool for optimisation or an addition to business plans. In some cases, the optimisation may also be achieved using traditional processes or statistical methods. If a clear benefit can be identified for the company, applications may create a competitive edge now, e.g. thanks to an extended product portfolio or cost reductions as a result of a reduced level of material stock. In addition, the framework conditions have developed in favour of AI applications in recent years: Cloud solutions allow data to be made available almost anywhere, the computing capacity of hardware continues to increase and the costs for data storage are significantly lower now than in the past.

Read more:

VDMA: Artificial intelligence position paperIn our personal lives, AI-based apps and assistants have been well-known for a while now (e.g. digital voice assistants on smartphones/smart home). Currently, typical areas of application for AI in the industrial environment are primarily in places where lots of data is (or could be) collected and analysed. The evaluation of large data volumes is one of the areas in which AI provides new opportunities in comparison with traditional business analytics solutions. In the field of quality assurance, optical inspections using AI applications are popular, which enable error or process analyses using image recognition. An energy management system that is equipped with AI is capable of analysing and predicting energy intake and distribution in the factory on a continuous basis in order to then adapt the manufacturing process and optimise the energy costs. Thanks to predictive data analysis, machines and systems can be maintained in a manner that is more well-suited to requirements and therefore reduce downtime. Outside of the company, the manufacturers of the machines and systems can provide additional services that are fed with the customers’ machine data on-site.

AI provides companies with support, in particular in areas in which humans and systems had previously reached their limits. In terms of analysis, AI applications generally use very large data volumes, which makes the identification of anomalies and the prediction of faults more accurate. With error reporting, AI makes it possible to identify causes more quickly and ascertain correlations that may have previously not been identified. AI can also help to plan manufacturing processes and capacities better, which has a positive effect on costs. Self-learning algorithms can make existing technologies even better. In this way, driverless transport systems can find the best path through the manufacturing facility at any time.

A BMWi projection indicates that an increase in the gross value added of EUR 31.8 billion for manufacturing businesses in Germany can be expected from 2019 to 2023 thanks to AI, which constitutes an enormous benefit for companies. A PWC study predicts a rise in the overall gross value added of EUR 430 billion.

Read more:

VDMA: Artificial intelligence position paper

BMWi study: The potential of AI in the manufacturing industry in Germany

PWC study: Effects of the use of AI in Germany

In most cases, from a medium-term to long-term perspective, business models without data components are hardly conceivable. The company structure is more virtual and the importance of platform-based business models in manufacturing (e.g. Bosch IoT Suite or Virtual Fort Knox) and in sales is on the rise. AI will help companies to manage the flood of data that is continuously increasing and use this. In this regard, AI can influence business models on various levels: Thanks to optimised resource and capacity planning, AI can make company processes faster and more efficient and therefore influence time, costs, quality and flexibility. Optimisation of the existing business model takes place on this level. As an additional service, AI can enhance the business model in the form of a data-based, intelligent addition to the product range. An example of this would be that of a mechanical engineer who, in addition to the machines that are sold, also offers a predictive maintenance service or even the machine run time as a service.

Read more:

PWC: White paper on the topic of artificial intelligence for accelerating innovationIn principle, all companies can profit from AI. AI is not comparable with high-performance computers or expensive robots because there are also small-scale and cost-efficient solutions (e.g. from Amazon or Google) and tools to try out (e.g. rapidminer or Knime). Most providers offer various services in the form of AI technologies but connect this with the use of their own cloud solution.

Read more:

See Question 21: What typical providers for AI solutions for medium-sized industrial companies exist?The first step is for each company to ascertain how the potential of AI can be used for them on an individual basis. In order to do so, companies can make use of the Scoutingservice by Allianz Industrie 4.0 and get inspiration from practical examples. On that basis, the next step is to determine whether there is concrete added value in process optimisation for the company in question and/or whether, in principle, the company’s own business model could be affected. In the event of process optimisation, a pilot or application field should be identified, as should suitable experts with knowledge of the processes and technical data understanding, either internally or externally. In general, you need to identify what data can be collected and is permissible to collect and which benefits this provides. Companies should develop the necessary data science expertise, consisting of a combination of practical knowledge and the fields of mathematics, statistics and IT, and look for (development) partners in their network for additional services, e.g. within the framework of events such as STARTUP THE FUTURE. Furthermore, it is advisable to inform the works council of the planned activities at an early stage as the works council has joint decision-making power in many fields, such as IT systems.

The CRISP model also provides orientation on the operative level for the development of an AI application scenario. This cross-industry process model describes a standardised procedure for implementing data mining projects in six phases.

Read more:

Allianz Industrie 4.0 Scouting

Events: STARTUP THE FUTURE, Events calendar by Allianz Industrie 4.0

In order to successfully use AI algorithms, the data quality and quantity from the field of machine learning is important. An AI application yields better results if more data is available for its training and operation and if the quality of the data is better and/or more suitable. If the quality of the data is insufficient, this increases the inaccuracy of the results. Other sub-areas of AI, for example logic, can manage with little data.

Often, data that is collected by companies is provided in an unstructured format, for example text, video or images, as it is not collected for the purpose of evaluation. Data must be structured in order to make it useable. Outdated or incorrect master data constitutes a particular problem. The specific data that is required depends on the application and the business case.

Administrating and managing data is a clear prerequisite for the implementation of AI application scenarios. In order to try out initial scenarios and small AI-based applications, however, smaller data volumes are sufficient.

In order to successfully implement an AI application scenario, the existing data is generally divided into three data sets. One is for training in order to provide the AI application with information at the initial stage. The second data set is used to test the AI application and, finally, this is validated using the third data set.

Within the framework of GDPR, the requirements for the protection of personal data became more stringent. For this reason, an expert should be consulted if personal data is used.

The required infrastructure for an AI application is determined by the purpose and the nature of the desired AI application. The more complex the AI application is and the more data that is to be processed, the higher the requirements in terms of hardware too. For simple image recognition applications, often the computing power of existing normal end devices is sufficient. If an application case involves high-resolution processing of camera data in real time, more computing power is required and processing should then run on a server or a Fog computer (cloud structure with decentralised computing power). Depending on the computing power that is required, a computer centre may even be necessary. In addition, cloud solutions can be interesting for SMEs because, depending on the type of cloud, no hardware investment is necessary and integration can be fast. When selecting a suitable cloud provider, the business conditions should be analysed in detail as some are not compliant with the European GDPR and data access regulations. In addition to the storage infrastructure of the cloud, some system providers also offer applications for data preparation and evaluation, which may be useful within the framework of AI applications.

Security concerns of companies are still amongst the greatest obstacles with regard to Industry 4.0 and cloud solutions. In addition, AI technology developments can also create entirely new security risks. The CyberProtect project predominantly supports SMEs in selecting secure software. Also, companies that develop their own software receive support to help them improve the security of their products and services. In addition to sophisticated technical security concepts, companies also need to keep in mind the organisation and employees as some employees may constitute a risk themselves, for example as a result of insufficient knowledge. Furthermore, current events and studies provide information and deliver the latest findings relating to the topic of cybersecurity.

Read more:

Funded project CyberProtect

McAfee: BigData Insider: White paper Big Data Security and Artificial Intelligence

BigData Insider: Whitepaper Big Data Security und Artificial Intelligence

Allianz Industrie 4.0: Events calendar

VDMA: Industrial Security

There is no clear answer to this question. Depending on the purpose of an AI application, the reliability can and may vary. The reliability of an application depends on various factors, for example the (Training) data that is used, the technology that is used etc. The algorithms that are used may also influence the reliability of the result.

Read more:

See Question 10: How much data and what data is required to use an AI application?

In Baden-Württemberg, as well as all over Germany, there are various laboratories and testing environments that conduct research on AI and in which you can experience live AI application cases (e.g. the Centre for Cyber Cognitive Intelligence, Future Work Lab). Furthermore, studies reference concrete application fields (e.g. robotics, quality management) and application scenarios (e.g. predictive maintenance, process control), that show initial potential. In addition, some companies and research organisation have also published the AI applications that they have implemented online and therefore made these accessible, at least in part.

Read more:

Allianz Industrie 4.0: 100 Places for Industry 4.0 in Baden-Wurttemberg

Learning systems platform: AI map with application scenarios

Fraunhofer-Allianz Big Data: Analysis of the future market for artificial intelligence – potential and applications

DFKI: Artificial intelligence – summit paper

Centre for Cyber Cognitive Intelligence CCI

Innovation laboratory Future Work Lab

The published cases in which an AI application has been unsuccessful are generally from the consumer sector. One example of unsuccessful use of a chatbot application is the e-assistant. After a user asked it to “call me an ambulance”, the chatbot referred to him as “an ambulance” from then on. Other well-known examples is that of Google image recognition, which incorrectly recognised people with dark skin as gorillas or the fatal accident caused by a Tesla Autopilot.

Read more:

University of Louisville/Microsoft Corporation: Collection and timeline of unsuccessful application scenarios

Over the course of the industrial revolution, workplaces changed significantly in the field of manufacturing. In recent years, a significant trend towards assisted workplaces has emerged, in which information is displayed in a context-sensitive and digital format. Physical assistance takes place using robots or exoskeletons, in particular in the field of monotonous or highly repetitive activities. In addition, there is an increasing level of individualisation of workplaces that had previously been homogenous. Much like the change from cubicles with dividing walls in large open-plan offices to individualised office rooms that are adapted to the needs of individual employees, a similar trend can be identified in areas that are closely related to manufacturing. Only part of the activities (e.g. simple data analyses, predictable physical activities) can be supported or carried out by AI assistants. AI systems must be understood as assistance systems for humans, not as systems that entirely substitute work being carried out by humans.

Read more:

There are various predictions relating to how many and which workplaces will be made redundant or changed by AI. However, no definitive conclusion can be drawn from this as some of the results differ to a large extent. There is a prediction that workplaces staffed by those with few qualifications, and those that involve routine manual and cognitive tasks, will be particularly threatened. At the same time, there are also discussions suggesting that, at the same time, new jobs will be created with cognitive/interactive and creative tasks. However, the skills and competencies required from employees will change drastically. In addition, statements regarding which roles will be affected varies in the projections because, in most cases, individual activities and not the entire role are affected.

In manufacturing work, simple, repetitive tasks or the acquisition and collection of data are considered to be more vulnerable to change or substitution than tasks which require the use of experience or human interaction.

Read more:

See Question 19: Where and how can companies train their employees on the topic of AI?

See Question 20: Can companies develop AI applications in their operations themselves or do they need to buy in AI specialist skills?

PWC: Study on the effects of the use of artificial intelligence in Germany

WEF: Report Future of Jobs

IAB: Discussion paper Promise or threat – The effects of a fourth industrial revolution on the labour market

IAB: Short report Few roles are keeping up with digitalisation

IAB: Job Futuromat

Open communication about upcoming changes at an early-stage is crucial for acceptance. In this regard, it is important to prepare the information for different interest groups within the company in terms of content, language and level of detail. In addition, explicit and implicit concerns need to be addressed openly. Communication must be honest and between equals. Involving employees in the new technologies (e.g. robots, digital assistance) can help to deal with rejection and spark interest. In addition, it is advisable to introduce AI applications to support work processes in a pilot area and to support other work steps (where possible) at a later point in time. If possible, participation in the project can take place at various levels. This contributes to encouraging the employees to identify with the solution. Visits to a laboratory with practical application scenarios helps to make AI more tangible, explain results from AI applications in a better manner and use examples to have an open discussion about the advantages and disadvantages.

Read more:

Centre for Cyber Cognitive Intelligence CCI

Innovation laboratory Future Work Lab

There are various formats for providing employees with further training. Talks and conferences make it easier to get involved in the field and provide orientation for the executive board and management. For developers, there are courses and further training opportunities (for example at the IHK), which provide a general overview with concise practical knowledge. Furthermore, innovative training providers offer further training courses to acquire methodical and industry-specific specialist knowledge, for example Fraunhofer-Allianz Big Data (data science training offered by Fraunhofer-Allianz Big Data). If a detailed basic training programme is required, special courses provide the necessary specialist knowledge in the fields of mathematics and computer science. Users can get to know the topic of AI on neutral ground in laboratories (e.g. Centre for Cyber Cognitive Intelligence or the Future Work Lab) and obtain some initial practical insights. In addition, there are free webinars online, for example on the topic of machine learning.

Read more:

Mooc.HOUSE: Machine learning

BITKOM Academy: Digital transformation seminar

Fraunhofer-Allianz Big Data: Data science training

Centre for Cyber Cognitive Intelligence CCI

Innovation laboratory Future Work Lab

Allianz Industrie 4.0: Events calendar

In principle, AI applications can be developed independently by companies if they have qualified employees and/or they can provide their employees with further training. In particular, a combination of process and data knowledge is required. In the event external experts are commissioned, it is still essential to develop expertise within your own companies, as the applications must be managed and “maintained” within the company. Employees that work directly with AI applications in the value creation chain do not need to have any detailed knowledge with regard to the application in most cases. If companies are not able to provide the relevant qualifications as a result of their size, then developing a qualified AI application network, e.g. with research organisations, AI application providers or in the context of research projects, is worthwhile. Further, the addition of a data specialist (“data scientist”) to selected project teams can help to realise potential within the company.

For medium-sized industrial companies, both well-known and experienced providers in the field of software and business intelligence can be contacts for applications (e.g. SAP, Microsoft), as can established start-ups (which, for example, provide innovative solutions). Depending on the scope and field of application of the required solution, cooperation with application-oriented research institutions may also be advantageous (e.g. for the method-based introduction of AI technologies). SMEs in particular can profit from start-ups, which can keep up well with the rapid developments in the field of AI thanks to their increased flexibility.

Read more:

Learning systems platform: AI map with application scenarios

Topbots: Map of providers of AI solutions

Fraunhofer-Allianz Big Data: General explanatory notes and information about platform providers (list of providers of various technologies, as well as research institutions that conduct research in this field)

At a state and national level, there are various funding services that specifically focus on providing support and financing for cooperation between companies and science. Furthermore, there are specific funding opportunities that are exclusively aimed at companies, such as the Digitalisierungsprämie Plus or the Innovationsgutschein Hightech Digital. Those who are interested can find informational and specialist events in the Allianz Industrie 4.0 events calendar, at which companies can make contact with the most important players in this field. Furthermore, the Federal Agency for Civic Education provides interesting expert contributions on its website. The IHK and some private providers are other points of contact for further training and support services. Companies can obtain support for their specific questions at independent advisory centres.

Read more:

Allianz Industrie 4.0 Baden-Württemberg events calendar

Learning systems platform website

AI association (KI-Verband) website

Website of the Federal Agency for Civic Education on the topic of AI

There’s no change without employees! With regard to AI, it is important to help employees deal with their concerns and get them involved. For companies, this means: providing information, enabling dialogue and encouraging people to talk about and deal with their concerns. Further training opportunities at an early stage make a positive contribution to creating an optimistic environment for employees and getting them involved in the change. In order to do so, the employee must have an understanding of the future requirements for employees (e.g. skills, qualifications).

Managers should deal with employees whose workplace will change in a focused manner. In doing so, satisfactory answers to any questions should be found and alternatives offered.

In the context of AI, the media often presents an exaggerated image with lots of negative impressions and suggestions of omnipotence, which creates a pessimistic view. Ethical use of AI is often deliberately played down. Pioneer companies have already created their own ethical guidelines for researching and developing AI in this regard. The final version of the EU Ethics Guidelines for Trustworthy Artificial Intelligence (AI) is expected to be published in April 2019. The Bundestag has also set up a Commission of Enquiry [Enquete-Kommission] in order to assess social responsibility, as well as the economic, social and environmental potential of AI.

Read more:

European Union: Preliminary version of the Ethics Guidelines

AI map

The AI map of the Plattform Lernende Systeme clearly depicts users and providers of artificial intelligence throughout Germany. It is constantly being expanded. Companies and institutions can register their AI solution.

We can only make efficient use of the mass of data available to us if we apply intelligent processes to it. Only then will we be able to understand what a treasure this data holds.

Lukas Schleicher

Project manager for artificial intelligence and cybersecurityLearning and qualification 4.0

Introduction

and questions

Best Practices

Learning Factories 4.0

Competition

Industry 4.0-Talents

Making employees fit for Industry 4.0

A changed working environment

Digitalization has far-reaching effects on industry: changes to processes, networking within the value chain, new technologies etc. This inevitably affects work; activities and entire workplaces are changing. Employers must make their employees fit for the new conditions.

That is why trainees and students are being prepared for a digitalized working world with new learning formats. Tailored qualification concepts must be developed for employees of all ages. After all, Industry 4.0 only works with people.

Many companies in Baden-Württemberg have long since recognized this and are specifically promoting the development of Industrie 4.0 skills.

Preparing for the digital future

Questions on the subject

What skills will employees need in the future?

According to the VDMA study „Qualification 2025„, there are rarely clear statements about required competencies for the skilled workers.

For this reason, the Allianz Industrie 4.0 initiated a project group to address this issue.

Which learning formats are suitable for preparing employees for the digital transformation?

Supporting work tools and communicable forms of work increase teaching and learning productivity.

Training and continuing education programs with an increasingly high proportion of IT skills are emerging.

New learning environments (e.g., learning factories) convey Industry 4.0 content and processes in a very practical way.

There are already many best practices that have taken up the new needs and developed solutions.

Translated with www.DeepL.com/Translator (free version)

What conditions must be in place for successful qualification?

Baden-Württemberg

Best Practices Learning and Qualification 4.0

Many companies and institutions have already developed and implemented different concepts to prepare tomorrow’s employees for new activities and work environments.

Discover more best practices at the „100 Places for Industry 4.0“ competition in the „Learning and HRM 4.0“ category.

Roadshow-Truck Discover Industry

Baden-Württemberg Stiftung gGmbH

DISCOVER INDUSTRY invites you into the world of Industry 4.0. At various workstations, students learn about the product creation process in industry through practical tasks. They also learn how engineers think and work in practice and what computer scientists have to do with the digitalized production of today and tomorrow.

EduKit goes IoT Kit

Adiro Automatisierungstechnik GmbH

The „EduKit PA goes IoT“ serves as a learning system for companies and institutions. The demonstrator in compact table format consists of an intelligent bottling plant that is networked with suppliers and customers via internet. This shows how industrial business processes are changing through information technology networking.

Industry 4.0 for everyone - The Learning Factory 4.0

Hohentwiel-Gewerbeschule Singen

The Learning Factory Singen regularly offers courses for industrial companies. Employees can thus expand their competencies in a time-based concept tailored to their needs. Trainers also use these courses for further training. There are courses in the areas of CADCAM (Solidworks/Heidenhain), PLC (TIA Portal) and robotics.

Industry 4.0 at vocational schools in Baden-Württemberg

Learning Factories 4.0 BW

To prepare skilled workers and junior staff for the requirements of Industry 4.0, the Ministry of Economics, Labor and Housing is promoting the establishment of Training Factories 4.0 at vocational schools. In the learning factories, students learn to operate equipment based on real industry standards.

The Learning Factory 4.0 is a laboratory that resembles industrial automation solutions in terms of its structure and equipment and in which basic principles for application-oriented processes can be learned. Mechanical and electrical engineering are linked by professional production control systems.

Target groups are

- trainees in dual training courses in the fields of metal and electrical engineering

- participants in technical schools and further education/training courses offered by medium-sized companies

as part of offers from the sponsoring associations of vocational schools and cooperative ventures with business organizations, applied Allianz Industrie 4.0 Baden-Württemberg.

Werner-von-Siemens-Schule Mannheim

Mannheim, Stadt Mannheim

https://www.wvss-mannheim.de

Friedrich-List-Schule Mannheim

Mannheim, Stadt Mannheim

https://www.fls-mannheim.de

Technische Schule Heidenheim

Heidenheim, Landkreis Heidenheim

www.heid-tech.de

Kaufmännische Schule Heidenheim

Heidenheim, Landkreis Heidenheim

www.ks-heidenheim.de

Technische Schule Heidenheim

Heidenheim, Landkreis Heidenheim

www.heid-tech.de

Kaufmännische Schule Heidenheim

Heidenheim, Landkreis Heidenheim

https://www.ks-heidenheim.de

Technische Schule Aalen

Ostalbkreis, Aalen

www.ts-aalen.de

Gewerbliche Schule Schwäbisch Gmünd

Ostalbkreis, Schwäbisch Gmünd

www.gs-gd.de

Gewerbliche Schule Ehingen

Ehingen, Alb-Donau-Kreis

https://www.gbs-ehingen.de

Robert-Bosch-Schule Ulm

Ulm, Stadt Ulm

https://www.rbs-ulm.de

Friedrich-List-Schule Ulm

Ulm, Stadt Ulm

https://www.fls-ulm.de

Karl-Arnold-Schule Biberach

Landkreis Biberach, Biberach

www.kas-bc.de

Elektronikschule Tettnang

Bodenseekreis, Tettnang

www.elektronikschule.de

Hohentwiel Gewerbeschule Singen, in Kooperation mit Zeppelin-Gewerbeschule Konstanz

Landkreis Konstanz, Singen

www.hgs-singen.de

Gewerbeschule Villingen-Schwenningen

Schwarzwald-Baar-Kreis, Villingen-Schwenningen

www.gewerbeschule-vs.de

Ferdinand-von-Steinbeis-Schule Tuttlingen

Tuttlingen, Landkreis Tuttlingen

https://steinbeisschule.de

Philipp-Matthäus-Hahn-Schule Balingen

Zollernalbkreis, Balingen

www.gsz-zak.de

Gewerbliche Schule Tübingen

Tübingen und Rottenburg, Landkreis Tübingen

https://www.gs-tuebingen.de

Berufliche Schule Rottenburg

Tübingen und Rottenburg, Landkreis Tübingen

https://www.bsrottenburg.de

Wilhelm-Schickard-Schule Tübingen

Tübingen und Rottenburg, Landkreis Tübingen

www.wss.tue.bw.schule.de

Ferdinand-von-Steinbeisschule Reutlingen

Landkreis Reutlingen, Reutlingen

www.steinbeisschule-reutlingen.de

Friedrich-Ebert-Schule Esslingen

„Multilabor 4.0“ für das Handwerk

Landkreis Esslingen

www.fes-es.de

Gewerbliche und Hauswirtschaftliche Schule Horb am Neckar

Horb am Neckar, Landkreis Freudenstadt

https://www.bs-horb.de

Berufliche Schulen Bretten

Bretten, Landkreis Karlsruhe

www.bsb-bretten.de

Albert-Einstein-Schule Ettlingen

Ettlingen, Landkreis Karlsruhe

www.aesettlingen.de

Gottlieb-Daimler-Schule 1 Sindelfingen

Sindelfingen, Landkreis Böblingen

https://www.gds1.de

Gottlieb-Daimler Schule 2 Sindelfingen

Sindelfingen, Landkreis Böblingen

https://www.gds2.de

Max-Eyth-Schule Kirchheim unter Teck

Kirchheim unter Teck, Landkreis Esslingen

www.mesk.de

Friedrich-Ebert-Schule Esslingen am Neckar

Esslingen am Neckar, Landkreis Esslingen

https://www.fes-es.de

Phillip-Matthäus-Hahn-Schule Nürtingen

Nürtingen, Landkreis Esslingen

www.pmhs-nuertingen.de

Werner-von-Siemens-Schule Mannheim

Mannheim, Stadt Mannheim

https://www.wvss-mannheim.de

Friedrich-List-Schule Mannheim

Mannheim, Stadt Mannheim

https://www.fls-mannheim.de

Gewerbliche Schule Geislingen

Geislingen, Landkreis Göppingen

https://www.gewerblicheschule.de

Kaufmännische Schule Geislingen

Geislingen, Landkreis Göppingen

https://www.ksgeislingen.de

Gewerbliche Schule Göppingen

Landkreis Göppingen, Göppingen

www.gs.gp.bw.schule.de

May-Eyth-Schule Stuttgart

Stadt Stuttgart, Stuttgart

www.mes-stuttgart.de

Werner-Siemens-Schule Stuttgart (Federführung)

Stadt Stuttgart, Stuttgart

www.wss-stuttgart.de

Robert-Bosch-Schule Stuttgart

Stadt Stuttgart, Stuttgart

www.rbs-stuttgart.de

Rhein-Neckar-Kreis, Wiesloch

www.hss-wiesloch.de

Ehrhart-Schott-Schule

Rhein-Neckar-Kreis, Schwetzingen

www.esss.de

Friedrich-Hecker-Schule

Rhein-Neckar-Kreis, Sinsheim

www.friedrich-hecker-schule.de

Theodor-Frey-Schule

Rhein-Neckar-Kreis, Eberbach

www.tfse.de

Hans-Freudenberg-Schule

Rhein-Neckar-Kreis, Weinheim

www.hfswe.de

Gewerbeschule Mosbach

Neckar-Odenwald-Kreis, Mosbach

www.gewerbeschule-mosbach.de

Zentralgewerbeschule Buchen

Neckar-Odenwald-Kreis, Buchen

www.zgb-buchen.de

Christian-Schmidt-Schule Neckarsulm

Neckarsulm, Landkreis Heilbronn

https://www.css-nsu.de

Andreas-Schneider-Schule Heilbronn

Heilbronn, Landkreis Heilbronn

https://www.ass-hn.com

Wilhelm-Maybach-Schule Heilbronn

Heilbronn, Stadt Heilbronn

www.wms-hn.de

Gustav-von-Schmoller-Schule Heilbronn

Heilbronn, Stadt Heilbronn

www.gvss-hn.net

Gewerbliche Schule Öhringen

Öhringen, Hohenlohekreis

www.gsoe.de

Gewerbliche Schule Künzelsau

www.gwkuen.de

Künzelsau, Hohenlohekreis

Gewerbliche Schulen

Landkreis Schwäbisch Hall, Schwäbisch Hall

gbs-sha.de

Kaufmännische Schulen

Landkreis Schwäbisch Hall, Schwäbisch Hall

www.kbs-sha.de

Gewerbliche Schulen

Landkreis Schwäbisch Hall, Crailsheim

www.gscr.de

Kaufmännische Schulen

Landkreis Schwäbisch Hall, Crailsheim

www.kscr.de

Gewerbliche Schule Bad Mergentheim

Bad Mergentheim, Main-Tauber-Kreis

www.gsmgh.de

Gewerbliche Schule Tauberbischofsheim

Tauberbischofsheim, Main-Tauber-Kreis

www.gstbb.de

Berufliches Schulzentrum Wertheim

Wertheim, Main-Tauber-Kreis

www.gstbb.de

Kaufmännische Schule Bad Mergentheim

Bad Mergentheim, Main-Tauber-Kreis

https://www.ks-mergentheim.de

Berufliches Schulzentrum Bietigheim-Bissingen in Kooperation mit Carl-Schaefer-Schule Ludwigsburg

Landkreis Ludwigsburg, Bietigheim-Bissingen

www.bsz-bietigheim.de

Berufliches Schulzentrum Bietigheim-Bissingen

Film über die Lernfabrik 4.0

Heinrich-Hertz-Schule

Stadt Karlsruhe, Karlsruhe

www.hhs.karlsruhe.de

Carl-Benz-Schule

Stadt Karlsruhe, Karlsruhe

www.cbs.ka.bw.schule.de

Carl-Benz-Schule Gaggenau

Landkreis Rastatt, Gaggenau

www.carl-benz-schule-gaggenau.de

Josef-Durler-Schule Rastatt

Rastatt, Landkreis Rastatt

https://jdsr.de

Handelslehranstalt Rastatt

Rastatt, Landkreis Rastatt

https://www.hla-rastatt.de

Carl-Benz-Schule Gaggenau

Gaggenau, Landkreis Rastatt

https://www.carl-benz-schule-gaggenau.de

Gewerblich-Technische Schule

Ortenaukreis, Offenburg

www.gs-offenburg.de

Richard-Fehrenbach-Gewerbeschule Freiburg

Freiburg, Stadt Freiburg im Breisgau

www.rfgs.de

Gewerbliche Schulen Donaueschingen

Donaueschingen, Schwarzwald-Baar-Kreis

www.gsdonau.de

Kaufmännische und Hauswirtschaftliche Schulen Donaueschingen

Donaueschingen, Schwarzwald-Baar-Kreis

www.khs-donaueschingen.de

Berufsschulzentrum Bietigheim-Bissingen

Bietigheim-Bissingen, Schwarzwald-Baar-Kreis

www.bsz-bietigheim.de

Hans-Thoma-Schule Titisee-Neustadt

Titisee-Neustadt, Landkreis Breisgau-Hochschwarzwald

www.hans-thoma-schule.de

Industry 4.0-Talents Competition

Industry 4.0-Talents

The digitalized processes in industry require corresponding skills and abilities of the employees. That is why Industry 4.0 skills must already be taught during training.

The „Industry 4.0 Talents“ competition is now making this visible:

We are looking for companies that have integrated Industry 4.0 projects into their training.

What are we looking for?

(1) innovative learning formats and training programs related to Industrie 4.0 in whose implementation or, where applicable, development trainees or students were actively involved

(2) innovative implementation projects related to Industrie 4.0 in which trainees or students were actively involved

Industry 4.0 requires new kinds of competencies in companies and adapted qualifications.

Jérôme Jetter

Project manager learning and qualification 4.0FAQ

Häufige Fragen

AI is a sub-area of computer science. As there is no clear definition for the term “intelligence” itself, there are various definitions for the term AI. In addition, understanding of AI has been developing on an ongoing basis. In general, AI engages with tasks or problems which human intelligence is normally required to solve. These processes aim to create self-learning intelligence in the form of a system that can work independently to develop solutions for a problem. In this regard, AI includes a range of methods from mathematics, statistics and computer science, which reconstruct particular aspects of human intelligence, for example cognitive or sensorimotor intelligence. This reconstructed human intelligence is only limited to a very specific area of application.

It is important to note that AI does not only relate to simple automation in which an application is programmed to make a particular decision in the event of a particular input.

Read more:

See Question 3: What other terms relating to AI do I need to know and where can I find a clear explanation of the relevant terms?AI in manufacturing is a key technology, making it part of digital transformation and therefore a significant element of Industry 4.0. Within the framework of discussions relating to Industry 4.0 and the respective application scenarios, AI plays a key role, for example in the analysis of large data volumes and in automated decision-making. Thanks to comprehensive networking and the collection of large volumes of data, which are developments associated with Industry 4.0, AI solutions are improving in terms of performance and may be used in the manufacturing environment.

An example of this is predictive maintenance: Manufacturing systems and machines will be maintained in a predictive manner on the basis of intelligent data analyses instead of at fixed intervals. An application based on AI provides additional opportunities here in the field of data analysis and pattern recognition, which enables maintenance times to be optimised.

Read more:

PWC-study: Predictive Maintenance 4.0Huber: Case studies on Predictive Maintenance (in the Data Science book)

Data Mining refers to the use of algorithms for the analysis and processing of large, complex and heterogenous data sets (“big data”) to generate new information. In this regard, individual data components are brought together, in particular, in order to obtain new findings.

Machine learning is a sub-area of AI. The focus is on the development of algorithms that imitate the learning behaviour of the human brain for machines. The algorithms learn from experiences and can find solutions for new problems or evaluate unknown data sets.

Deep learning is a sub-area of machine learning that is characterised by complex solution methods. It uses artificial neural networks, in which multiple data processing levels can be combined.

Models that are based on artificial neural networks constitute the networking of nerve cells from a brain in an abstract form for information processing.

Weak artificial intelligence solves problems using methods that have been developed and optimised for the specific purpose (e.g. spam filters).

Strong artificial intelligence, also known as superintelligence , is superior to humans in terms of intellectual abilities. On the basis of the current knowledge, strong artificial intelligence does not yet exist.

For some of the terms that are listed, a concrete definition has not been established.

Read more:

Federal government: Artificial intelligence strategy of the federal government

Start-up scene: Artificial intelligence glossary

Elektronikpraxis Vogel: Artificial intelligence specialist terms

VDMA: Machine learning in machine and systems engineering

Fraunhofer Society: Artificial intelligence trends

Fraunhofer-Allianz Big Data: 2017 potential assessment for AI

AI is no longer just something for the future. AI is already making it possible to achieve significant progress in various areas of applications, for example in industry, the transport sector, healthcare and other areas of life. For AI applications it is important to identify solutions from the perspective of need and to evaluate AI as a tool for optimisation or an addition to business plans. In some cases, the optimisation may also be achieved using traditional processes or statistical methods. If a clear benefit can be identified for the company, applications may create a competitive edge now, e.g. thanks to an extended product portfolio or cost reductions as a result of a reduced level of material stock. In addition, the framework conditions have developed in favour of AI applications in recent years: Cloud solutions allow data to be made available almost anywhere, the computing capacity of hardware continues to increase and the costs for data storage are significantly lower now than in the past.

Read more:

VDMA: Artificial intelligence position paperIn our personal lives, AI-based apps and assistants have been well-known for a while now (e.g. digital voice assistants on smartphones/smart home). Currently, typical areas of application for AI in the industrial environment are primarily in places where lots of data is (or could be) collected and analysed. The evaluation of large data volumes is one of the areas in which AI provides new opportunities in comparison with traditional business analytics solutions. In the field of quality assurance, optical inspections using AI applications are popular, which enable error or process analyses using image recognition. An energy management system that is equipped with AI is capable of analysing and predicting energy intake and distribution in the factory on a continuous basis in order to then adapt the manufacturing process and optimise the energy costs. Thanks to predictive data analysis, machines and systems can be maintained in a manner that is more well-suited to requirements and therefore reduce downtime. Outside of the company, the manufacturers of the machines and systems can provide additional services that are fed with the customers’ machine data on-site.

AI provides companies with support, in particular in areas in which humans and systems had previously reached their limits. In terms of analysis, AI applications generally use very large data volumes, which makes the identification of anomalies and the prediction of faults more accurate. With error reporting, AI makes it possible to identify causes more quickly and ascertain correlations that may have previously not been identified. AI can also help to plan manufacturing processes and capacities better, which has a positive effect on costs. Self-learning algorithms can make existing technologies even better. In this way, driverless transport systems can find the best path through the manufacturing facility at any time.

A BMWi projection indicates that an increase in the gross value added of EUR 31.8 billion for manufacturing businesses in Germany can be expected from 2019 to 2023 thanks to AI, which constitutes an enormous benefit for companies. A PWC study predicts a rise in the overall gross value added of EUR 430 billion.

Read more:

VDMA: Artificial intelligence position paper

BMWi study: The potential of AI in the manufacturing industry in Germany

PWC study: Effects of the use of AI in Germany

In most cases, from a medium-term to long-term perspective, business models without data components are hardly conceivable. The company structure is more virtual and the importance of platform-based business models in manufacturing (e.g. Bosch IoT Suite or Virtual Fort Knox) and in sales is on the rise. AI will help companies to manage the flood of data that is continuously increasing and use this. In this regard, AI can influence business models on various levels: Thanks to optimised resource and capacity planning, AI can make company processes faster and more efficient and therefore influence time, costs, quality and flexibility. Optimisation of the existing business model takes place on this level. As an additional service, AI can enhance the business model in the form of a data-based, intelligent addition to the product range. An example of this would be that of a mechanical engineer who, in addition to the machines that are sold, also offers a predictive maintenance service or even the machine run time as a service.

Read more:

PWC: White paper on the topic of artificial intelligence for accelerating innovationIn principle, all companies can profit from AI. AI is not comparable with high-performance computers or expensive robots because there are also small-scale and cost-efficient solutions (e.g. from Amazon or Google) and tools to try out (e.g. rapidminer or Knime). Most providers offer various services in the form of AI technologies but connect this with the use of their own cloud solution.

Read more:

See Question 21: What typical providers for AI solutions for medium-sized industrial companies exist?The first step is for each company to ascertain how the potential of AI can be used for them on an individual basis. In order to do so, companies can make use of the Scoutingservice by Allianz Industrie 4.0 and get inspiration from practical examples. On that basis, the next step is to determine whether there is concrete added value in process optimisation for the company in question and/or whether, in principle, the company’s own business model could be affected. In the event of process optimisation, a pilot or application field should be identified, as should suitable experts with knowledge of the processes and technical data understanding, either internally or externally. In general, you need to identify what data can be collected and is permissible to collect and which benefits this provides. Companies should develop the necessary data science expertise, consisting of a combination of practical knowledge and the fields of mathematics, statistics and IT, and look for (development) partners in their network for additional services, e.g. within the framework of events such as STARTUP THE FUTURE. Furthermore, it is advisable to inform the works council of the planned activities at an early stage as the works council has joint decision-making power in many fields, such as IT systems.

The CRISP model also provides orientation on the operative level for the development of an AI application scenario. This cross-industry process model describes a standardised procedure for implementing data mining projects in six phases.

Read more:

Allianz Industrie 4.0 Scouting

Events: STARTUP THE FUTURE, Events calendar by Allianz Industrie 4.0

In order to successfully use AI algorithms, the data quality and quantity from the field of machine learning is important. An AI application yields better results if more data is available for its training and operation and if the quality of the data is better and/or more suitable. If the quality of the data is insufficient, this increases the inaccuracy of the results. Other sub-areas of AI, for example logic, can manage with little data.

Often, data that is collected by companies is provided in an unstructured format, for example text, video or images, as it is not collected for the purpose of evaluation. Data must be structured in order to make it useable. Outdated or incorrect master data constitutes a particular problem. The specific data that is required depends on the application and the business case.

Administrating and managing data is a clear prerequisite for the implementation of AI application scenarios. In order to try out initial scenarios and small AI-based applications, however, smaller data volumes are sufficient.

In order to successfully implement an AI application scenario, the existing data is generally divided into three data sets. One is for training in order to provide the AI application with information at the initial stage. The second data set is used to test the AI application and, finally, this is validated using the third data set.

Within the framework of GDPR, the requirements for the protection of personal data became more stringent. For this reason, an expert should be consulted if personal data is used.

The required infrastructure for an AI application is determined by the purpose and the nature of the desired AI application. The more complex the AI application is and the more data that is to be processed, the higher the requirements in terms of hardware too. For simple image recognition applications, often the computing power of existing normal end devices is sufficient. If an application case involves high-resolution processing of camera data in real time, more computing power is required and processing should then run on a server or a Fog computer (cloud structure with decentralised computing power). Depending on the computing power that is required, a computer centre may even be necessary. In addition, cloud solutions can be interesting for SMEs because, depending on the type of cloud, no hardware investment is necessary and integration can be fast. When selecting a suitable cloud provider, the business conditions should be analysed in detail as some are not compliant with the European GDPR and data access regulations. In addition to the storage infrastructure of the cloud, some system providers also offer applications for data preparation and evaluation, which may be useful within the framework of AI applications.

Security concerns of companies are still amongst the greatest obstacles with regard to Industry 4.0 and cloud solutions. In addition, AI technology developments can also create entirely new security risks. The CyberProtect project predominantly supports SMEs in selecting secure software. Also, companies that develop their own software receive support to help them improve the security of their products and services. In addition to sophisticated technical security concepts, companies also need to keep in mind the organisation and employees as some employees may constitute a risk themselves, for example as a result of insufficient knowledge. Furthermore, current events and studies provide information and deliver the latest findings relating to the topic of cybersecurity.

Read more:

Funded project CyberProtect

McAfee: BigData Insider: White paper Big Data Security and Artificial Intelligence

BigData Insider: Whitepaper Big Data Security und Artificial Intelligence

Allianz Industrie 4.0: Events calendar

VDMA: Industrial Security

There is no clear answer to this question. Depending on the purpose of an AI application, the reliability can and may vary. The reliability of an application depends on various factors, for example the (Training) data that is used, the technology that is used etc. The algorithms that are used may also influence the reliability of the result.

Read more:

See Question 10: How much data and what data is required to use an AI application?

In Baden-Württemberg, as well as all over Germany, there are various laboratories and testing environments that conduct research on AI and in which you can experience live AI application cases (e.g. the Centre for Cyber Cognitive Intelligence, Future Work Lab). Furthermore, studies reference concrete application fields (e.g. robotics, quality management) and application scenarios (e.g. predictive maintenance, process control), that show initial potential. In addition, some companies and research organisation have also published the AI applications that they have implemented online and therefore made these accessible, at least in part.

Read more:

Allianz Industrie 4.0: 100 Places for Industry 4.0 in Baden-Wurttemberg

Learning systems platform: AI map with application scenarios

Fraunhofer-Allianz Big Data: Analysis of the future market for artificial intelligence – potential and applications

DFKI: Artificial intelligence – summit paper

Centre for Cyber Cognitive Intelligence CCI

Innovation laboratory Future Work Lab

The published cases in which an AI application has been unsuccessful are generally from the consumer sector. One example of unsuccessful use of a chatbot application is the e-assistant. After a user asked it to “call me an ambulance”, the chatbot referred to him as “an ambulance” from then on. Other well-known examples is that of Google image recognition, which incorrectly recognised people with dark skin as gorillas or the fatal accident caused by a Tesla Autopilot.

Read more:

University of Louisville/Microsoft Corporation: Collection and timeline of unsuccessful application scenarios

Over the course of the industrial revolution, workplaces changed significantly in the field of manufacturing. In recent years, a significant trend towards assisted workplaces has emerged, in which information is displayed in a context-sensitive and digital format. Physical assistance takes place using robots or exoskeletons, in particular in the field of monotonous or highly repetitive activities. In addition, there is an increasing level of individualisation of workplaces that had previously been homogenous. Much like the change from cubicles with dividing walls in large open-plan offices to individualised office rooms that are adapted to the needs of individual employees, a similar trend can be identified in areas that are closely related to manufacturing. Only part of the activities (e.g. simple data analyses, predictable physical activities) can be supported or carried out by AI assistants. AI systems must be understood as assistance systems for humans, not as systems that entirely substitute work being carried out by humans.

Read more:

There are various predictions relating to how many and which workplaces will be made redundant or changed by AI. However, no definitive conclusion can be drawn from this as some of the results differ to a large extent. There is a prediction that workplaces staffed by those with few qualifications, and those that involve routine manual and cognitive tasks, will be particularly threatened. At the same time, there are also discussions suggesting that, at the same time, new jobs will be created with cognitive/interactive and creative tasks. However, the skills and competencies required from employees will change drastically. In addition, statements regarding which roles will be affected varies in the projections because, in most cases, individual activities and not the entire role are affected.

In manufacturing work, simple, repetitive tasks or the acquisition and collection of data are considered to be more vulnerable to change or substitution than tasks which require the use of experience or human interaction.

Read more:

See Question 19: Where and how can companies train their employees on the topic of AI?

See Question 20: Can companies develop AI applications in their operations themselves or do they need to buy in AI specialist skills?

PWC: Study on the effects of the use of artificial intelligence in Germany

WEF: Report Future of Jobs

IAB: Discussion paper Promise or threat – The effects of a fourth industrial revolution on the labour market

IAB: Short report Few roles are keeping up with digitalisation

IAB: Job Futuromat

Open communication about upcoming changes at an early-stage is crucial for acceptance. In this regard, it is important to prepare the information for different interest groups within the company in terms of content, language and level of detail. In addition, explicit and implicit concerns need to be addressed openly. Communication must be honest and between equals. Involving employees in the new technologies (e.g. robots, digital assistance) can help to deal with rejection and spark interest. In addition, it is advisable to introduce AI applications to support work processes in a pilot area and to support other work steps (where possible) at a later point in time. If possible, participation in the project can take place at various levels. This contributes to encouraging the employees to identify with the solution. Visits to a laboratory with practical application scenarios helps to make AI more tangible, explain results from AI applications in a better manner and use examples to have an open discussion about the advantages and disadvantages.

Read more:

Centre for Cyber Cognitive Intelligence CCI

Innovation laboratory Future Work Lab

There are various formats for providing employees with further training. Talks and conferences make it easier to get involved in the field and provide orientation for the executive board and management. For developers, there are courses and further training opportunities (for example at the IHK), which provide a general overview with concise practical knowledge. Furthermore, innovative training providers offer further training courses to acquire methodical and industry-specific specialist knowledge, for example Fraunhofer-Allianz Big Data (data science training offered by Fraunhofer-Allianz Big Data). If a detailed basic training programme is required, special courses provide the necessary specialist knowledge in the fields of mathematics and computer science. Users can get to know the topic of AI on neutral ground in laboratories (e.g. Centre for Cyber Cognitive Intelligence or the Future Work Lab) and obtain some initial practical insights. In addition, there are free webinars online, for example on the topic of machine learning.

Read more:

Mooc.HOUSE: Machine learning

BITKOM Academy: Digital transformation seminar

Fraunhofer-Allianz Big Data: Data science training

Centre for Cyber Cognitive Intelligence CCI

Innovation laboratory Future Work Lab

Allianz Industrie 4.0: Events calendar

In principle, AI applications can be developed independently by companies if they have qualified employees and/or they can provide their employees with further training. In particular, a combination of process and data knowledge is required. In the event external experts are commissioned, it is still essential to develop expertise within your own companies, as the applications must be managed and “maintained” within the company. Employees that work directly with AI applications in the value creation chain do not need to have any detailed knowledge with regard to the application in most cases. If companies are not able to provide the relevant qualifications as a result of their size, then developing a qualified AI application network, e.g. with research organisations, AI application providers or in the context of research projects, is worthwhile. Further, the addition of a data specialist (“data scientist”) to selected project teams can help to realise potential within the company.

For medium-sized industrial companies, both well-known and experienced providers in the field of software and business intelligence can be contacts for applications (e.g. SAP, Microsoft), as can established start-ups (which, for example, provide innovative solutions). Depending on the scope and field of application of the required solution, cooperation with application-oriented research institutions may also be advantageous (e.g. for the method-based introduction of AI technologies). SMEs in particular can profit from start-ups, which can keep up well with the rapid developments in the field of AI thanks to their increased flexibility.

Read more:

Learning systems platform: AI map with application scenarios

Topbots: Map of providers of AI solutions

Fraunhofer-Allianz Big Data: General explanatory notes and information about platform providers (list of providers of various technologies, as well as research institutions that conduct research in this field)

At a state and national level, there are various funding services that specifically focus on providing support and financing for cooperation between companies and science. Furthermore, there are specific funding opportunities that are exclusively aimed at companies, such as the Digitalisierungsprämie Plus or the Innovationsgutschein Hightech Digital. Those who are interested can find informational and specialist events in the Allianz Industrie 4.0 events calendar, at which companies can make contact with the most important players in this field. Furthermore, the Federal Agency for Civic Education provides interesting expert contributions on its website. The IHK and some private providers are other points of contact for further training and support services. Companies can obtain support for their specific questions at independent advisory centres.

Read more:

Allianz Industrie 4.0 Baden-Württemberg events calendar

Learning systems platform website

AI association (KI-Verband) website

Website of the Federal Agency for Civic Education on the topic of AI

There’s no change without employees! With regard to AI, it is important to help employees deal with their concerns and get them involved. For companies, this means: providing information, enabling dialogue and encouraging people to talk about and deal with their concerns. Further training opportunities at an early stage make a positive contribution to creating an optimistic environment for employees and getting them involved in the change. In order to do so, the employee must have an understanding of the future requirements for employees (e.g. skills, qualifications).

Managers should deal with employees whose workplace will change in a focused manner. In doing so, satisfactory answers to any questions should be found and alternatives offered.

In the context of AI, the media often presents an exaggerated image with lots of negative impressions and suggestions of omnipotence, which creates a pessimistic view. Ethical use of AI is often deliberately played down. Pioneer companies have already created their own ethical guidelines for researching and developing AI in this regard. The final version of the EU Ethics Guidelines for Trustworthy Artificial Intelligence (AI) is expected to be published in April 2019. The Bundestag has also set up a Commission of Enquiry [Enquete-Kommission] in order to assess social responsibility, as well as the economic, social and environmental potential of AI.

Read more:

European Union: Preliminary version of the Ethics Guidelines

FAQ

Häufige Fragen

Insbesondere der Bereich der sozialen Kompetenzen nimmt einen zunehmenden Stellenwert für den Unternehmenserfolg ein. Während bisher aus methodischer Sicht der Aspekt der Routine wichtig war, müssen FacharbeiterInnen 4.0 in Zukunft verstärkt teamfähig sein, um sich untereinander in komplexeren Situationen zu koordinieren und effizient zu arbeiten (siehe „Kompetenz- und Qualifizierungsbedarfe bis 2030“, Bundesministerium für Arbeit und Soziales).

Als digital natives fällt Auszubildenden der Umgang mit digitalen Bedienschnittstellen meist leicht. Neben dem vermehrten Einsatz digitaler Medien, die sich aus diesem Grund anbieten, heben neue Formate großes Potential, Auszubildende noch besser auf die Tätigkeiten im Unternehmen vorzubereiten. Beispiele hierfür sind:

- Frühzeitige Fähigkeits-Potenzial-Workshops: Diese erlauben es AusbilderInnen vor allem soziale Kompetenzen und Motivationen der Auszubildenden einzuschätzen. Hierfür bieten sich offene Problemstellung an, die in Teams gelöst werden. Dabei steht der Lernerfolg weniger im Vordergrund (ein außergewöhnliches Beispiel, das sich adaptieren lässt, ist der Eierwettbewerb). Relevanter ist die Beobachtung der Auszubildenden durch die AusbilderInnen. So werden vielversprechende Kommunikationsmuster für die jeweiligen Auszubildenden (z. B. vermehrtes Loben) sehr früh identifiziert, ggf. passende Ausbildungsformate gewählt oder bestehende Formate leicht angepasst.

- Interdisziplinäre Workshops: In diesen Workshops arbeiten Auszubildende aus verschiedenen Fachbereichen zusammen an einer Problemstellung. Dies fördert die Vermittlung fachlich übergreifenden Wissens sowie die Teamfähigkeit. Auszubildende in höheren Lehrjahren können auch in Aspekten wie Problemlösungsfähigkeit, Stressresistenz und Selbstständigkeit gestärkt werden, indem das Umfeld von Workshops im geschützten Raum durch zunehmende Zielvorgaben (z. B. Zeitlimits) und ggf. deren Prüfung verändert wird.

- Projektarbeit: Im Wesentlichen ähneln Projektarbeiten den oben genannten Workshops und vermitteln die gleichen Kompetenzen. Unterschiede sind die längere Dauer (bzw. zeitliche Verteilung der Tätigkeiten) und das geringere Maß an Interaktion mit den AusbilderInnen während der Projektarbeit. Welche Kompetenzen im Vordergrund stehen, kann bspw. durch Gruppengröße und Umfang bzw. den Anspruch des Projekts gesteuert werden.

Bei den Vorreitern der Digitalisierung ist der Einsatz von Smartphones, Tablets oder Laptops in der Ausbildung Alltag. Damit können z. B. Lernplattformen mit digitalen Lerninhalten sowie das digitale Ausbildungsheft aufgerufen werden. Viele Unternehmen gehen aber noch weiter. Im Folgenden werden einige Beispiele beschrieben:

Für die Ausbildung in der Zerspanung können virtuelle Anlagen die Ausstattung der Lehrwerkstatt ergänzen. Zum einen bieten diese Simulatoren die Möglichkeit, den Maschinenpark kostengünstig virtuell zu erweitern und damit mehr Auszubildenden zeitgleich Zugriff zu ermöglichen. Zum anderen werden Fehler bei der Einrichtung der Anlage angezeigt und verursachen keine Reparatur- und Ausfallkosten. Das Erlernen des Umgangs mit den realen Maschinen ersetzt der Simulator aber nicht vollständig und nach der Einlernphase erfolgt der Abschluss des Ausbildungsmoduls an der realen Maschine.

Auch der Aufbau einer Lern-Fertigungslinie mit Industrie 4.0-Inhalten ist sehr beliebt. Eine solche Fertigungslinie bestehend aus bspw. einem Förderband und einem Leichtbauroboter kann von den Auszubildenden in Projektarbeit aufgebaut und stetig weiterentwickelt werden. Dabei lernen sie etwas über den Umgang mit Robotern sowie über deren Steuerung und Programmierung. Ferner kann Auszubildenden die Möglichkeit gegeben werden, Erfahrungen mit der Prozesssteuerung und Fernüberwachung von Produktionslinien zu sammeln. Die reale Anlage steht bspw. in Berlin, sie wird aber von Auszubildenden aus Baden-Württemberg betreut.

Nicht immer muss es eine ganze Produktionslinie sein. Auch der Einsatz von Miniaturanlagen speziell für den Ausbildungsbetrieb erfreut sich zunehmender Beliebtheit. Diese Anlagen bilden den Stand der Technik modernster Anlagen ab, wie z. B. Fernüberwachung zu einem vergleichsweisen geringeren Preis, und ermöglichen das Erlernen unterschiedlichster Geschäftsprozesse eines Werkzeugmaschinenbauunternehmens. Zudem kann die Anlage natürlich auch für entsprechende Ausbildungsmodule (z. B. Zerspanung an einer Mini-CNC) eingesetzt werden.

Ein sehr beliebtes Format für kleinere Digitalisierungsprojekte ist die Vorbereitung von Aufbauten für lokale Ausbildungsmessen oder andere öffentliche Events, bei denen ein gewisser WOW-Effekt ausgelöst werden soll. Z. B. können mittels Augmented Reality-Brillen die Produkte des Unternehmens dargestellt werden. Gerade wenn gezielt für das Unternehmen als innovativer Ausbildungsort geworben werden soll, kann dabei Gamification (also ein spielerischer Charakter der Nutzererfahrung) mehr Aufmerksamkeit bei der Zielgruppe erzeugen.

Für die Ausbildung 4.0 ist eine sehr enge Kommunikation zwischen LehrerInnen in Berufsschulen und AusbilderInnen in Industrieunternehmen notwendig, da in diesen Lernortkooperationen beidseitig positive Effekte entstehen. So können sich BerufsschullehrerInnen über aktuelle Themen in der Industrie informieren und diese in den Unterricht einfließen lassen. Die AusbilderInnen lernen im Gegenzug Veränderungen im schulischen Lehrplan besser kennen und können diese in die Planungen der Praxisteile einfließen lassen. Gerade im Aufbau von Workshops und Projekten kann dies hilfreich sein.

Ein weiterer Punkt ist die Nutzung von Lernfabriken in den Berufsschulen. Jede zweite Berufsschul ein Baden-Württemberg hat bereits eine Lernfabrik, in denen Industrie 4.0-Inhalte gelehrt werden können. Eine Kooperation zwischen der Vermittlung der Industrie 4.0-Inhalte in den Lernfabriken sowie praktischen Anwendungen in der Industrie ist für die Auszubildenden häufig förderlich.

Um diese engere Verknüpfung zwischen schulischer Ausbildung und Ausbildung im Unternehmen zuschaffen, müssen AusbilderInnen und BerufsschullehrerInnen proaktiv aufeinander zugehen und selbst Austauschformate, wie z. B. Unternehmensbesuche oder Themenabende, organisieren.

FAQ

Most frequent questions and answers

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar leo.I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar leo.I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar leo.I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar leo.I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar leo.I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar leo.I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar leo.I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar leo.I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar leo.I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar leo.

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, adipiscing elit. Ut elit tellus, luctus nec mattis, pulvinar dapibus leo.

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus ullamcorper mattis, pulvinar dapibus leo.

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut luctus nec ullamcorper mattis, pulvinar dapibus leo.